Modular construction is gaining serious momentum in the construction industry, and for good reasons. With an increasing demand for faster, more sustainable, and cost-effective building methods, it offers a compelling alternative to traditional techniques.

This article explores what modular construction is all about and why it is reshaping the construction industry.

What is Modular Construction?

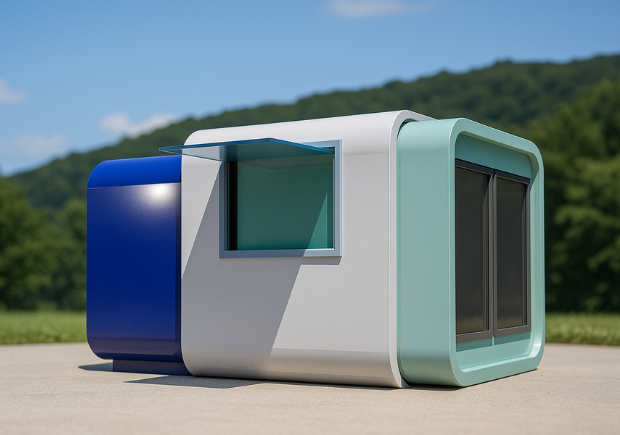

Modular construction, also known as modular building, is a form of prefabricated construction. Here, structures are built in individual sections called “modules”, and this is done off-site, under controlled factory conditions. The modules are then transported to the construction site and assembled into a complete building.

Usually, each module is constructed using the same materials used in traditional construction. They are also done in line with the same codes and standards as conventional buildings, ensuring structural integrity, durability, and compliance with local regulations.

However, unlike conventional building, which happens entirely on-site and is often subject to delays due to weather or labor shortages, modular building is faster, safer, and allows for more efficient project delivery.

Modular Construction vs Traditional Construction

While both methods have their place in the building industry, we will need to consider their differing attributes. Therefore, here are the differences between traditional and modular construction:

Construction Site: Usually, structures built using modular construction are built off-site in a factory, then assembled on-site. In traditional construction, however, you build the entire structure on-site from the ground up.

Timeline: Because site work and module fabrication happen simultaneously in modular building, the process is usually faster, whereas it is slower when building traditionally because of the sequential construction process required.

Quality Control: Due to factory conditions and the fact that the quality of the materials used is more likely to be properly checked in modular building, there is a high consistency in the quality of the structures. However, in conventional construction, quality may vary depending on site conditions and labor.

Labour: Modular construction typically requires fewer on-site workers since it is done in an enclosed factory environment. Meanwhile, traditional construction is labor-intensive, usually requiring a full crew on-site.

Waste Management: Because modules are built in a controlled factory setting, there is usually less material waste since leftover materials can easily be reused and properly disposed of. In contrast, there is usually higher material waste from cutting and overordering in traditional construction. The leftover materials are also more prone to improper discarding since they are usually just left on-site until construction is completed, and sometimes, they end up buried in the soil.

Flexibility: Modular structures are usually easy to expand or relocate since they are made using individual modules, but traditionally built structures are usually permanent and can’t be relocated. Expanding them also requires a lot of money and strenuous work.

Clearly, modular construction offers a more forward-looking solution that meets the increasing demands for speed, sustainability, and cost-efficiency.

Where Modular Construction is Used

Modular construction is incredibly versatile and is used across a wide range of sectors, including:

- Residential Housing: E.g., single-family homes, apartment complexes, affordable housing, and so on.

- Commercial Buildings: E.g., offices, retail stores, hotels, etc.

- Healthcare: E.g., clinics, hospitals, emergency response units, etc.

- Education: E.g., classrooms, dormitories, training centers, etc.

- Industrial: E.g., site offices, warehouses, control rooms, etc.

- Public Sector: E.g., military housing, prisons, government facilities, and so on.

Moreover, with its adaptability and efficiency, it is especially popular in areas where speed, cost control, or environmental concerns are top priorities.

Benefits of Modular Construction

1. Speedy Construction

One of the biggest advantages of modular building is speed. This construction method significantly reduces build times by allowing site preparation and module fabrication to happen at the same time. This parallel workflow helps complete projects 30–50% faster than conventional builds, making it ideal for time-sensitive developments like schools, hospitals, or housing.

2. Cost Efficiency

With reduced labor costs, less material waste, and shorter timelines, this construction method often results in more predictable and often lower total costs. It also minimizes expenses related to project delays and on-site inefficiencies since factory-based production helps prevent weather interruptions or subcontractor scheduling issues, which are common in traditional construction.

3. Improved Safety

Construction sites are among the most hazardous workplaces. Modular building, however, reduces on-site labor, which in turn lowers the risk of accidents and injuries. In addition, factory settings offer safer, ergonomically designed workspaces with strict adherence to health and safety regulations, reducing exposure to dangerous conditions for workers and nearby residents.

4. Sustainability and Waste Reduction

Sustainability is a core advantage of this method of construction. This is because factories can optimize material use with precision, reducing waste by up to 80% compared to traditional methods. Many modular projects also incorporate recycled or eco-friendly materials and use energy-efficient systems, making them very suitable for the environment.

5. Design Flexibility and Scalability

Contrary to popular belief, modular construction isn’t limited to cookie-cutter designs. It allows for a wide range of customization, from floor plans and finishes to architectural styles. Additionally, one can easily expand, disassemble, or relocate modular buildings.

Conclusion

In summary, modular construction isn't just a trend; it's a strategic, innovative solution to the evolving demands of the construction industry. With faster timelines, improved quality, and a significantly reduced environmental footprint, it's no wonder more developers, engineers, and architects are steadily making the switch.

Whether you’re building affordable housing or luxury high-rises, Redcity offers modular construction services that will get your project done faster, safer, and more sustainably. To join in on the trend, simply request a quote here and discover how we can get you started. If you would also like to check out our other construction services, visit here. While you’re at it, also visit our blog and YouTube channel for more insightful news and content like this.

Would you consider using this ingenious method of construction? Let us know your thoughts in the comments.